Undergraduate Research Assistant

Xiao Su Group, University of Illinois at Urbana Champaign (May 2019 - Present)

Electrochemical R&D.

I have been working in Professor Xiao Su’s electrochemical separation lab to create and test molecularly selective electrodes for removal of toxic contaminants as well as recovery of valuable catalysts and other materials from water.

Arsenic Project

I worked on an arsenic removal project when I first joined the lab. Experimentation had already been done to suggest that when a potential is applied, PVF polymer is able to selectively adsorb arsenic ions. Another polymer, TEMPO, was shown to convert the more toxic arsenite into a less toxic arsenate. My project applied the previously used techniques to a flow cell to exhibit the viability of this method for real world application. The work I completed is included in this paper.

Gold Project

This semester I am working on a gold recovery project. If successful, this could revolutionize the way that gold is separated from other ore and recycled electronics parts. This method has the potential to be much more cost effective, efficient, and produce less waste than current separation methods. The theory is promising and I am excited to dive into this project!

Group Outreach

Our research group was asked to participate in an annual engineering outreach event called WYSE. This event aims to educate high school students about the different types of engineering through lectures and demos. Our group adapted a filtration demo I had done previously for AIChE. We gave students the goal of building the most efficient filtration system out of supplies like water bottles, filter paper, coffee filters, sand, cloth, a coagulant, and an adsorbent. We taught them basic filtration principles and assisted them as they worked in teams to create a system to remove turbidity and fluorescence from water samples we gave them.

Innovation Engineering Intern

Water Mission, Charleston SC (May 2020 - Aug 2020)

Chemical and Electrical Engineering

Water Mission is an engineering nonprofit focused on using first class engineering solutions to end the global water crisis. I spent the summer in Charleston working within the Innovation Engineering team.

Wireless Float Switch Project

The other engineering intern and I spent most of the summer working on this project on and off. The purpose of this was to test out a new system with a transmitter, receiver, and relay that would be used as a wireless float switch in the field. We ordered parts and soldered the parts on printed circuit boards (PCBs) to use as power sources, gathering power from a solar array to power the board and charge batteries. We also spent quite a few days walking around North Charleston with these circuit boards, a multimeter, and yagi antennas to test the range. In our last week, we went to test the system at the beach where we could get an accurate baseline, without interference from cars, buildings, and trees. We were able to conclude the project and determine that the cost of employing this wireless system wouldn’t be low enough to be competitive with the previously used wired system at the range we were able to find.

Indonesia Design Project

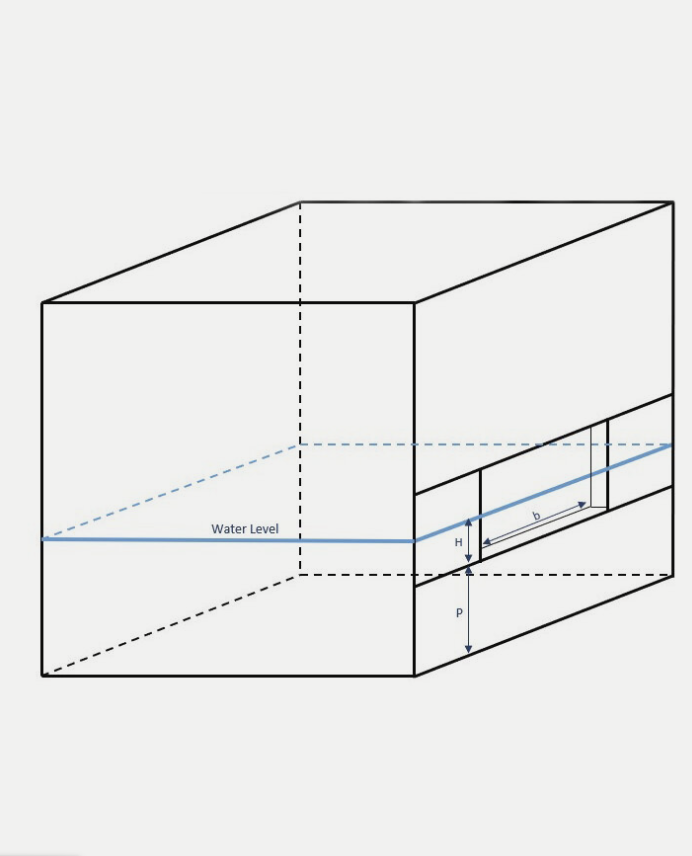

This was my favorite project where I was really able to use my chemical engineering background and shine. Water Mission is working with Grundfos to install a pump, storage, and filtration system in Indonesia. We were tasked with designing a system that collected and stored water from a stream and pumped the water to another storage tank. We used the distance and height difference between the tanks, the head required to run the turbine, the type of pipe, and cost of different sized pipes to determine the diameter of piping to be used. We also found the desired specifications of a weir and baffle for the original storage tank to take care of excess water and to ensure a minimal amount of sand particles enter the turbine.

Pressure Relief Valve Project

After ordering a new batch of pressure relief valves (PRVs) in March, Water Mission found that their PRVs had been failing regularly. The innovation engineering team designed and ran an experiment to test these PRVs. We used four valve bodies, four pistons, and over 100 o-rings to test different combinations for failures. After finding consistent failures, we decided to try different o-ring materials and sizes. We found that smaller, EPDM o-rings worked as a mitigating solution. This $0.50 solution was able to solve the problem instead of spending $50.00 + to buy a more traditional PRV for their hundreds of affected systems.

Tanzania Aux Power Box Project

As someone with very little ECE experience, this project taught me a lot and took me out of my comfort zone. First, our supervisor taught us the basics of electricity and circuits and sent us to YouTube to learn about KiCAD. He then gave us a schematic file of an auxiliary power box he designed and told us to make it better and teach him what we learn. The other intern and I spent many of our remote days working on this project, learning the software, and teaching each other what we learned. After we found a good system of importing the parts we needed, we organized our schematics and then used that to create a printed circuit board. We figured out how to import DRS files and designed circuit boards to minimize box size and cost. Between our supervisor and the two of us, we didn’t formally know the functions and workings of KiCAD. After this project, we were able to learn a lot and teach our supervisor a few things that he wasn’t previously aware of.

PID Control Project

This was another fun project where I was able to use some chemical engineering knowledge. Water Mission had already had quite a few systems in place that used an RSI solar converter and a 4-20 mA flow signal. Our job was to figure out how to use the RSI’s PID (proportional integral derivative) control features to control the flow rate of water. Because I was the only one on our team with a chemical engineering background and knowledge of PID controls, I gave my supervisor and co-intern a presentation on the basics of PID control. After that, we designed a piping system that would connect to a pump and would let us manipulate the flow (using valves) and send the flow signal to the RSI. We found all the parts we needed and cemented them all together. After setting this up and wiring the RSI, flowmeter, and 9900 signal transmitter, we started familiarizing ourselves with the controls. After trying a lot of different settings and changing different parameters, we were finally able to achieve PID control. With this information, we created a twelve page manual to communicate the process and the reason for and theory of PID control in our systems. I was even able to use my photoshop skills to make some nice schematics!

Learning and Professional Growth

This was a great summer of learning and growing in the most supportive professional atmosphere I have experienced. I was especially appreciative of how much our supervisor taught us. Even if we didn't need to know the theory or background of something to do our job, he would still take time out of his work to teach us. In addition to our main projects, we also were able to do little projects like setting up a solar array for a desired voltage/current window, setting up and testing an RO system, collecting flowmeter data, building instrumentation and control panels for use in a Tanzanian refugee camp, performing pressure tests for chlorinator bowls, and calibrating instrumentation for pressure and flow measurement.

We were also really lucky to be able to tag along with our supervisor in his meetings with the Water Mission team, corporate partners, and potential partners. We were able to meet with department heads in communication, community development, and other essential parts of Water Mission to learn about how all these parts work together to provide people with safe water.